Seamless Guttering

Aluminium seamless guttering is a cost effective and far superior alternative to traditional pre-cut plastic guttering

What is seamless guttering?

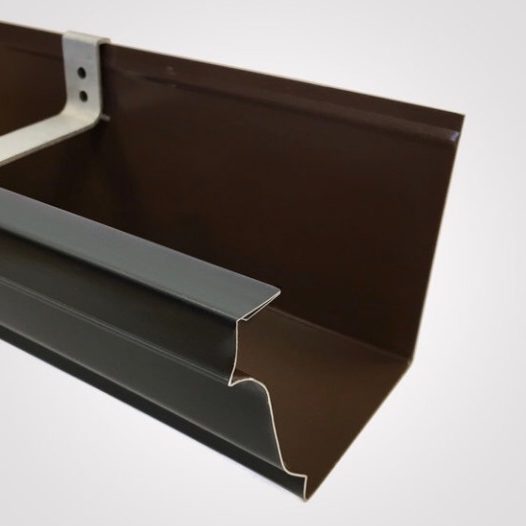

Seamless is a continuous length of guttering. Very long continuous lengths of aluminium can be produced and installed thus eliminating the presence of any joints and therefore any potential for leaks.

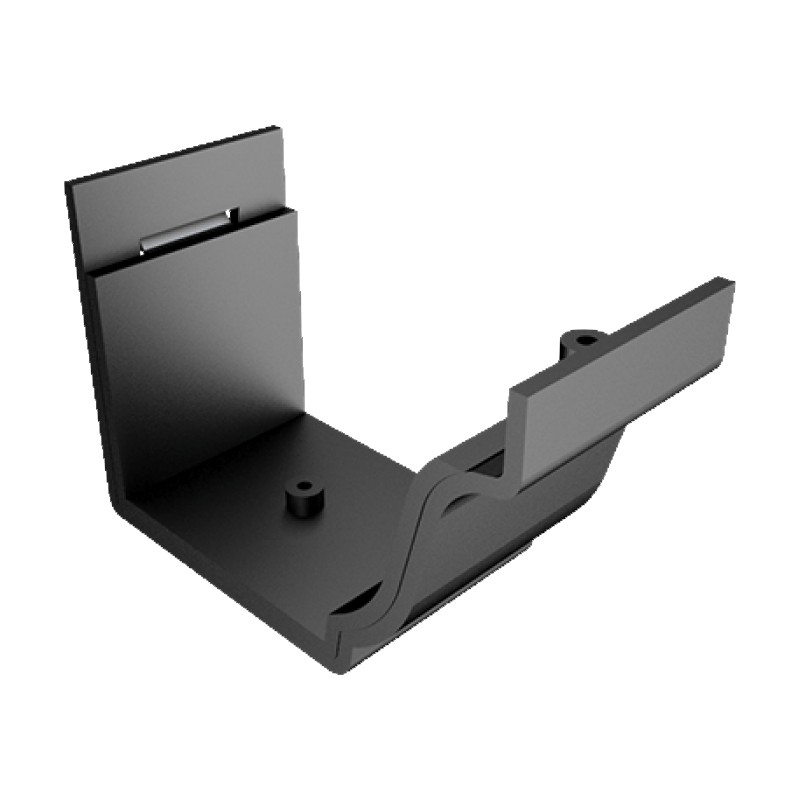

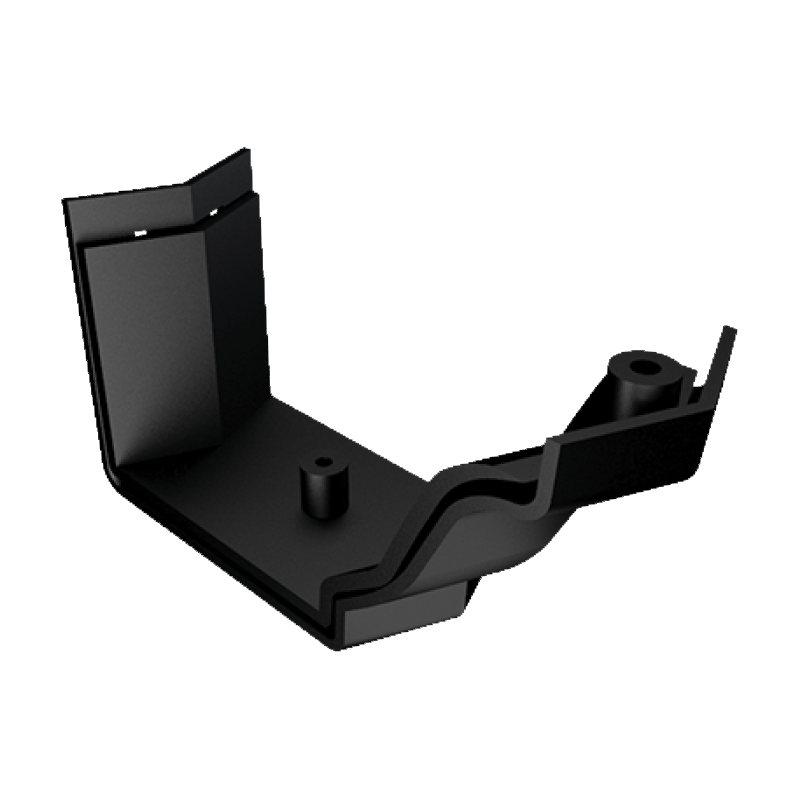

The brackets are concealed inside the gutter (they are not visible to the eye). These brackets provide extra strength within the guttering but, being hidden, they allow a smooth appearance and clean lines.

Aluminium seamless guttering is a perfect choice for traditional or modern properties.

Call our experts on 01756 533357 or

Get a quote

Why choose seamless guttering?

Aluminium seamless guttering offers a cost effective and far superior alternative to traditional pre-cut plastic guttering systems

No more rusty gutters

Pre-painted with a non-corrosive coating, aluminium seamless guttering will not need repainting for 25-35 years.

No more leaks

The continuous lengths of seamless guttering are jointless, therefore preventing any leaks.

No more clutter

Mounted using hidden hangers, giving a clean run of guttering that's pleasing to the eye.

BBA Certified guttering

Advanced Guttering use the only BBA certified seamless aluminium gutter system available the UK.

The BBA - the British Board of Agrément - sets, maintains and drives high quality standards in construction through construction product certification.

The certified machines we use - the Mustang® seamless aluminium gutter system - roll lengths of up to 30 metres on site. It is a unique guttering option with no joints( meaning no leaks!), creating a neat, maintenance free gutter of the highest quality.

Since 1991 Mustang® has been the only seamless aluminium gutter system available with BBA approval in the UK. The certified seamless guttering it produces gives you peace of mind and the added extra of the visual appeal of smooth neat lines.

Manufactured from 90% recycled aluminium - which can be further recycled once it has reached the end of its useful life long into the future – it really is an environmentally friendly product compared with joined sections of plastic.

The seamless aluminium guttering and aluminium downpipes we install are available in black, white, brown & anthracite grey.

Composition & manufacture

This certified gutter system has become a popular choice for specifiers, architects and construction companies all over the UK. We've been working with it for many years.

- Gutter formed on site from Hydrocoat Textured 800 Aluminium 0.9mm thick 3105 grade H45 Coil

- Components made from colour matched UV stable Polycarbonate Matt Finish (40% reflectivity)

- BBA Certificate No 91/2625

- Life expectancy of over 30 years

How is seamless guttering

made and fitted?

Seamless guttering is produced on site by a specialist roll-forming gutter machine.

It is rolled and shaped out of specialist gutter forming machines built into our vehicles.

Stainless steel rollers form the guttering on site to the exact measurements needed to fit your property.

Colour options

Matt black

Satin white

Matt brown

Matt anthracite

Seamless guttering installation

Our expert installation team will come equipped to site with the latest seamless aluminium guttering cutting equipment.

We are able to keep wastage and costs to an absolute minimum, as our guttering is made to measure.

- Quick, easy and safe to install

most of the work is done on the ground. - No maintenance

fit and forget! - Strong and fit for purpose

with a life expectancy in excess of 30 years accredited by the BBA - Quality assured

the only seamless aluminium gutter system with BBA approval in the UK - No wastage

made to the exact dimensions of the building on site - Sustainable product

manufactured using recycled aluminium - Done right

Installed by our experienced fitters - Suitable for all uses

Seamless guttering can be fitted back to all types of fascias, brick or stone. - Fits in

Range of colour and style options available

Examples of our seamless guttering installations

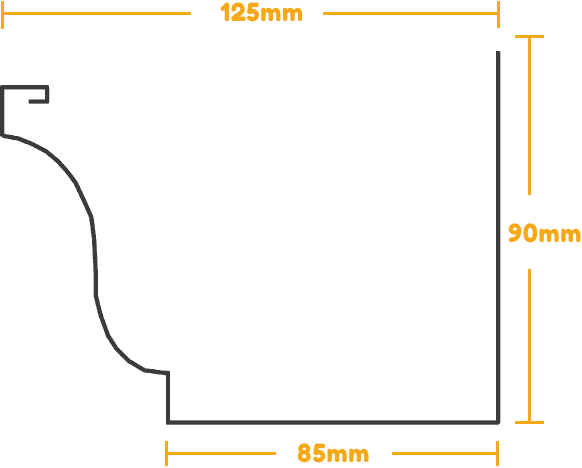

Gutter sizes and profile

Any gutter length is possible - it is roll formed on-site to any continuous length. Seamless Aluminium Guttering is available in two sizes. One size for domestic applications and another size for commercial buildings:

Standard domestic guttering

125mm x 90mm (Domestic) - 125mm being the catchment area of the gutter and 90mm being the back edge height.

This size of gutter would normally be used on domestic houses & maisonettes.

Larger guttering

150mm x 130mm (Commercial) - 150mm being the catchment area of the gutter and 120mm being the back edge height.

This size of gutter would normally be used on bigger properties i.e. schools, offices, churches and even some large houses.

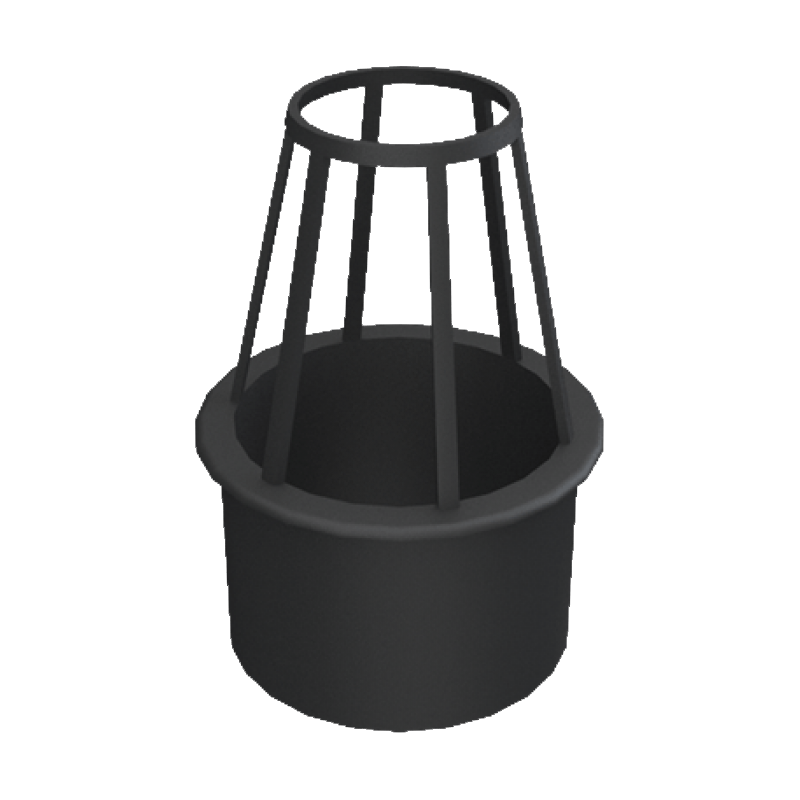

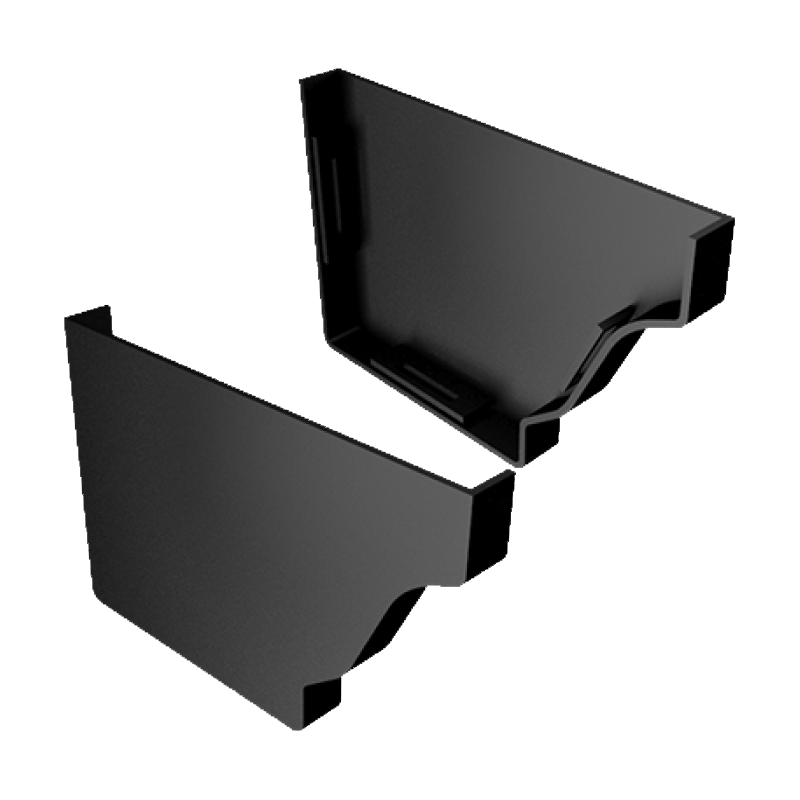

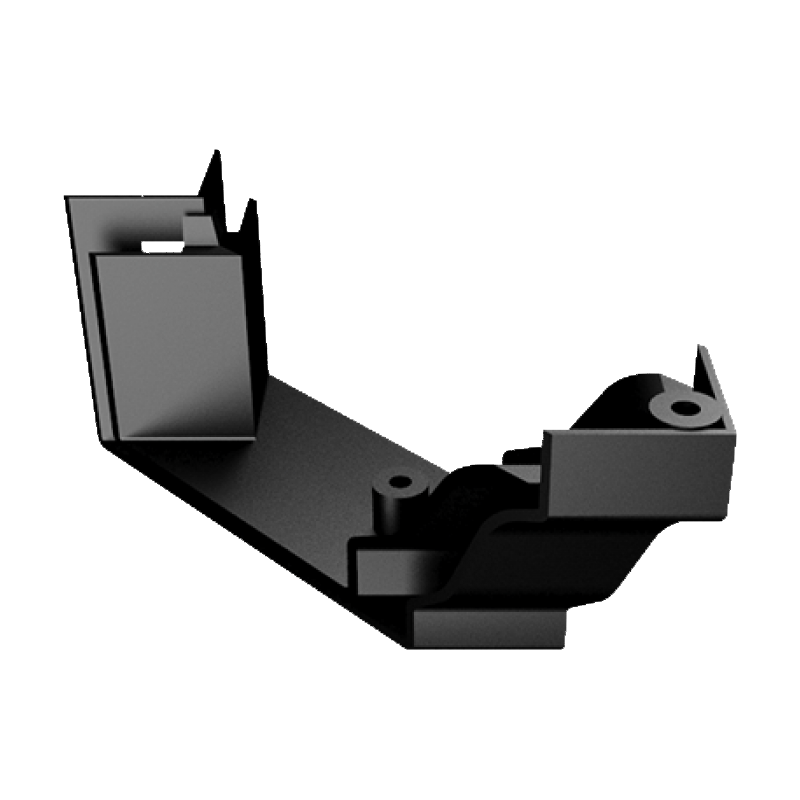

Gutter accessories

The installation process

- Downpipes are positioned and marks corresponding to their centres are made on the fascia board. An exact measurement is taken of the length of gutter required, noting the marked positions of the downpipes.

- An initial 1m length of the gutter section is roll-formed and the process stopped for an end cap to be fitted to the open end.

- The gutter is crimped centrally near the edge of the rear, front and base to create raised fixing nibs.

- The end cap is pressed home activating the internal slotted securing clips to fully engage over the fixing nib, ensuring a non-removable fitting. The completed fitting is sealed inside the gutter with at least three beads of sealant, minimum diameter 7mm.

- Roll-forming to the exact gutter length is then completed. Aluminium fixing brackets are clipped into position at centres not exceeding 450mm as roll-forming is continued.

- The formed gutter is cut to length and a stopend fitted to the remaining open end.

- Corners are formed by mitring the ends of the gutter lengths and connecting with a two-piece polycarbonate locking corner fitting, which is then sealed with a specific sealant and secured with stainless steel screws.

- Connector expansion joints are installed in the same manner.

- The corners and connectors do not require mechanical fixing and allow for thermal movement. At the downpipe positions in the gutter a hole is formed using a Q-Max cutter into which a low-density polyethylene outlet/leaf trap is fitted and sealed with mastic.

- The gutter is positioned and fixed with 4mm diameter, 30mm long stainless steel, self tapping screws.

- The fixings are located in pre-drilled holes in the fixing brackets and driven through the back of the gutter into the fascia.

Where we install seamless guttering

From our base on the border of North Yorkshire, West Yorkshire and Lancashire, we're just a few minutes away from and regularly fit guttering in: